SMEDDS in softgel capsules: opportunities and pitfalls

What are SMEDDS, and what is their role in softgel capsules? In this short article, we breakdown the key points of SMEDDS.

What are SMEDDS?

SMEDDS is an acronym for Self Micro-Emulsifying Drug Delivery System. SMEDDS formulations are a clear solution of a drug substance that spontaneously forms an oil-in-water (O/W) microemulsion upon dispersion in water. In the emulsion, the drug substance is incorporated within droplets with a size of 50-200 µm. A SMEDDS formulation typically contains a lipid solvent, one or more surfactants, and optionally a co-solvent.

Why are SMEDDS used in drug formulations?

SMEDDS formulations can significantly increase the solubility of a drug substance and ensure that it remains in solution during the passage through the gastrointestinal tract. In addition, some of the lipid components that are frequently used can also increase the bioavailability of the drug substance utilizing increased absorption or limited digestion. SMEDDS formulations are therefore most frequently used for substances with poor solubility and/or poor absorption, i.e. BCS class II or IV. However, other substance classes may also benefit from a SMEDDS formulation, e.g. in case of significant food effect on the bioavailability of the drug substance. SMEDDS formulations can also be used for oral delivery of peptides, as they may limit their digestion.

What is the difference between SEDDS, SMEDDS, and SNEDDS?

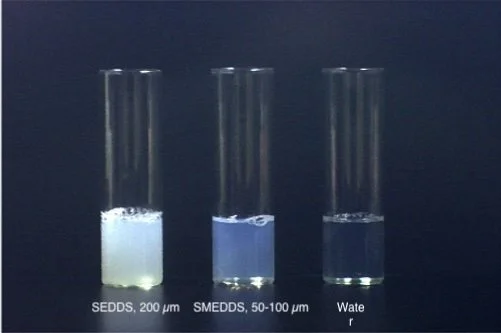

The main difference between the three types of self-micro emulsifying systems is the droplet size of the emulsion in water: While a SEDDS system also spontaneously forms an emulsion upon contact with water, the droplet size is in the upper range of 100-250 µm. A SNEDDS emulsion has a droplet size in the nanometer range of approx. <100 nm. The appearance of a SMEDDS emulsion is blueish, and opalescent, while a SEDDS formulation forms a turbid emulsion; a SNEDDS emulsion in water is clear and transparent.

Appearance of SEDDS and SMEDDS after dispersion in water

Can a SMEDDS be encapsulated into a softgel capsule?

SMEDDS formulations are frequently used as the fill of softgel capsules to mask their commonly unpleasant taste and due to the possibility of preparing single-dose units. However, as SMEDDS mostly contain hydrophilic components, there is a significant interaction potential with the gelatin shell. For example, migration of plasticizer and water may cause brittleness of the shell. On the other hand, migration of hydrophilic co-solvents may cause precipitation of the drug substance and impact its bioavailability. Another common issue is the crosslinking of the gelatin shell, which decreases its solubility and may also impact the bioavailability of the drug.

Most of these issues can be evaluated early on and prevented by the appropriate selection of the excipient palette for fill and shell.

For more information on the most common pitfalls during the development of softgel capsules, download our exclusive report.

Can SMEDDS be encapsulated into a hard capsule?

In contrast to softgel capsules, hard capsules don´t contain plasticizer in the shell and their shell is much thinner. Use of hydrophilic fill formulation therefore quickly may lead to brittle capsules. Encapsulation of SMEDDS into hard capsules is therefore not recommended.

What are examples of SMEDDS formulations in softgel capsules?

Examples of commercial softgel capsules containing SMEDDS formulations include Neoral (Ciclosporin), the first commercial SMEDDS soft gel capsule product, Rydapt (Midostaurin), and Norvir (Ritonavir).

Our online softgel course is now live!

After years of requests, we've packaged our expertise into comprehensive training courses:

+ Practical formulation knowledge based on 15+ years of experience

+ Solutions to common quality issues like leakage and crosslinking

+ Available on-demand access—learn whenever and wherever you want